VSR is gaining popularity due to its ease of use, mobility and flexibility.

The main applications of this process is for stress relieving of weld fabrications during and on completion of welding, intermediate and final stress relieve of machined items requiring strict dimensional tolerance control and stress relief of rotating equipment prior to use.

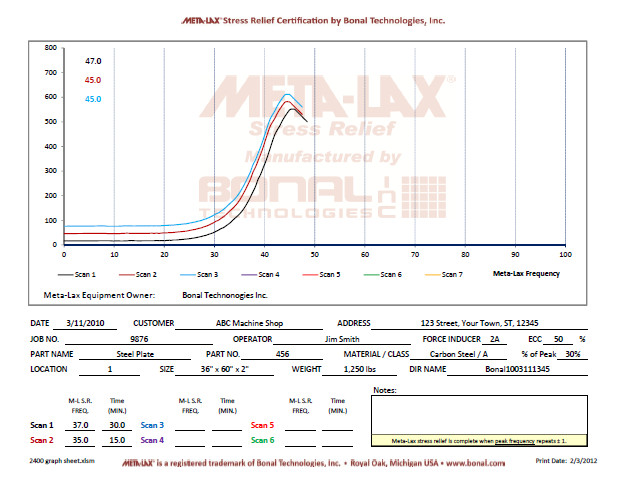

A valuable tool provided by this process is the ability to monitor a physical response of the metal / item being treated which indicates the success of and completion stage of the stress relieving.

This type of stress relief can only be applied to items with thermally induced stresses and has very limited application for stresses induced by cold forming.

Please contact us for more information and to determine the applicability of Vibration Stress Relieving to your requirements.